Introduction

In today’s high-tech manufacturing world, Industrial automation PCB assembly automation is more than a trend—it’s the future.

As industries embrace digital transformation, the demand for reliable, high-performance electronics is rapidly increasing.

At the heart of these smart systems lies the printed circuit board (PCB), an unsung hero that powers everything from robotic arms to advanced telecommunication systems.

For businesses looking to stay ahead, choosing a capable partner for PCB fabrication and assembly is crucial. That’s where Global Well PCBA, a leading Chinese PCB and PCBA manufacturer, comes into play.

With cutting-edge technologies, English-language support, and a reputation for delivering quality, Global Well PCBA has become a go-to name for companies worldwide looking to optimize their electronics supply chain.

This article explores the role of PCBs in industrial automation, the benefits of advanced PCB solutions like Rigid-Flex and High Frequency PCBs, and how manufacturers like Global Well PCBA are driving the industry forward.

The Role of PCBs in Industrial Automation

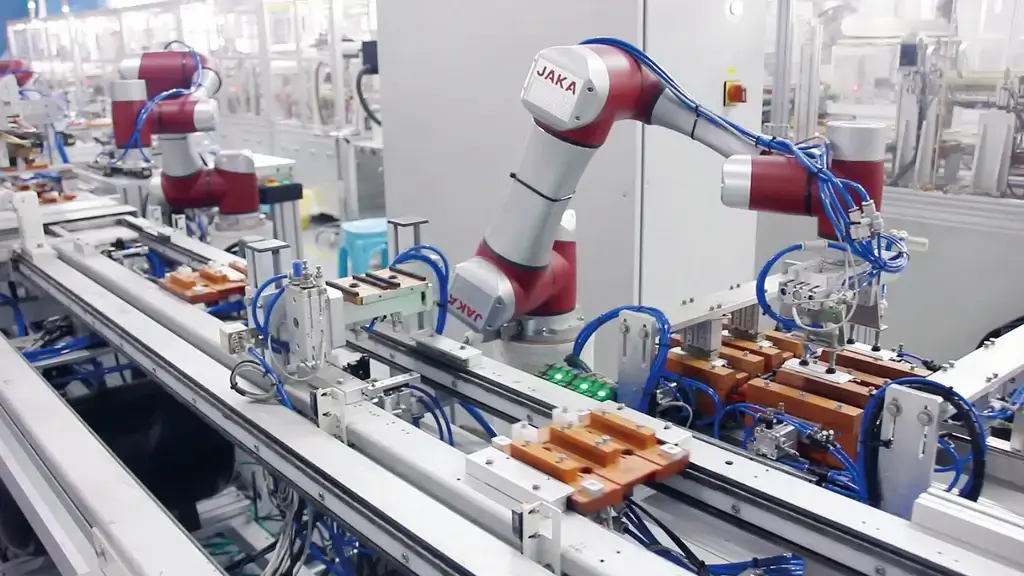

Industrial automation relies on complex systems of sensors, actuators, controllers, and power units—all of which are built on PCBs.

These boards act as the nervous system for automation machinery, transmitting signals, controlling operations, and ensuring high-speed communication between subsystems.

Whether it’s a CNC machine, a robotic assembly line, or an automated logistics system, PCBs are essential for:·

- Signal Integrity and Reliability: High-speed data transfer and real-time responsiveness are critical in automated systems. PCBs ensure consistent signal transmission with minimal interference

- Compact Design: Automation often requires compact yet powerful control systems. PCBs allow high-density circuit integration in limited spaces.

- Customization: Industrial environments vary greatly, and so do their electronic needs. PCBs can be customized for specific voltage requirements, load tolerances, and environmental resilience.·

With the growing complexity of industrial equipment, there is an increasing need for specialized PCB solutions that go beyond conventional designs.

Advanced PCB Technologies Powering Automation

Modern industrial electronics are evolving to meet the demands of higher performance, durability, and miniaturization. In this environment, basic single or double-layer PCBs may no longer be sufficient. Let’s look at some of the advanced PCB technologies that are shaping the future of industrial automation.

1. Rigid-Flex PCBs

Rigid-Flex PCBs combine the stability of rigid boards with the flexibility of flex circuits. These are particularly valuable in applications that require bending or where space is at a premium.

Advantages of Automation:

- Improved mechanical performance in dynamic environments

- Reduced wiring and connectors, minimizing failure points

- Enhanced resistance to vibration and shock

In robotic arms or CNC tools with moving joints, Rigid-Flex boards reduce weight and increase durability.

2. High-Frequency PCBs

High-frequency PCBs are used in applications that require the transmission of high-speed signals. These boards use special materials like PTFE (Teflon) to ensure minimal signal loss and interference.

Use Cases:

- Industrial IoT sensors that transmit real-time data

- Wireless communication modules in automated systems

- Radar and positioning systems in automated vehicles

As smart factories become more reliant on real-time data and wireless connectivity, High-Frequency PCBs are becoming indispensable.

3. HDI (High-Density Interconnect) PCBs

HDI PCBs offer more interconnections in a smaller area, enabling the miniaturization of control modules without sacrificing performance.

Applications:

- Compact control panels

- Embedded systems in robotics

- Edge computing devices for local data processing.

4. Metal Core PCBs

When heat dissipation is a concern, such as in motor drivers or high-power LEDs, Metal Core PCBs are used. Their enhanced thermal management makes them ideal for power electronics in automation.

Industrial Automation PCB Assembly: Partnering with the Right Manufacturer

Assembling PCBs for industrial automation requires more than just soldering components onto a board. It involves:

- Precise Component Placement: Tolerance for error is minimal in industrial electronics.

- Quality Assurance: Testing under various conditions (thermal cycling, vibration) is vital.

- Material Expertise: Choosing the right substrate and finish is key for performance and longevity.

For companies seeking a reliable manufacturing partner, Global Well PCBA offers a distinct advantage. They bring:·

- One-Stop PCB and PCBA Services: From design review to final assembly and testing, Global Well PCBA provides end-to-end services.·

- Advanced Capabilities: Support for multilayer boards, Rigid-Flex designs, High Frequency materials, and fine-pitch component assembly.

- Global Quality Standards: ISO-certified production and RoHS-compliant materials.·

- Efficient Turnaround: Ideal for both prototype runs and large-volume manufacturing.

- English-Language Support: Facilitating easy communication for international clients.

Applications Across Industries

Let’s take a closer look at how Global Well PCBA’s solutions are being applied in real-world scenarios across industries:

1. Telecommunications

High-frequency PCBs are central to telecommunication infrastructure. Whether it’s a base station or a 5G antenna module, precision and low signal loss are critical. Global Well PCBA’s experience with high-speed materials like Rogers and Taconic makes them a strong partner for telecom OEMs.

2. Robotics

In robotics, compactness and durability are essential. Rigid-Flex PCBs, combined with HDI layout, allow manufacturers to create powerful control units in tight spaces. Applications include autonomous mobile robots (AMRs), robotic arms, and drones.

3. Medical and Laboratory Equipment

Though technically outside industrial automation, many medical systems share the same reliability demands. Diagnostic equipment, for instance, uses high-precision PCBs for data acquisition and control. Global Well PCBA’s cleanroom-compatible facilities and high-mix production capability suit such applications.

4. Energy and Power Management

Smart grids and industrial energy storage systems require durable, high-current PCBs. Metal core PCBs and thick copper boards from Global Well PCBA ensure longevity and safety in power-critical environments.

Why Choose Global Well PCBA?

In a crowded marketplace, choosing a PCB manufacturer can be daunting. What sets Global Well PCBA apart?

- Technical Expertise: Years of experience with complex PCB designs, including Rigid-Flex and HDI boards.·

- Customization: Tailored solutions based on the client’s technical requirements.

- Competitive Pricing: Cost-effective production without compromising on quality.

- Transparency: Real-time updates, DFM (Design for Manufacturability) feedback, and accessible customer support.

- Global Reach: Serving clients across the Americas, Europe, and Asia with seamless logistics and customs handling.

The Future of PCB Assembly in Automation

The future of industrial automation hinges on smarter, more connected, and more efficient systems. This trend demands PCBs that are:·

- Smaller and more powerful

- Highly reliable under stress

- Capable of supporting wireless communication and real-time data processing·

From AI-powered robotics to machine learning-driven predictive maintenance systems, tomorrow’s industrial systems will be deeply dependent on sophisticated electronics—and by extension, advanced PCBs.

Manufacturers like Global Well PCBA are not just keeping pace with this evolution—they’re helping to lead it.

Conclusion

As industrial automation expands, so does the need for more advanced and reliable PCB solutions. Technologies like Rigid-Flex, High Frequency, and HDI PCBs enable the next generation of manufacturing equipment. However, these innovations are only as good as the partners you work with.

Global Well PCBA stands out as a leading Chinese manufacturer offering world-class capabilities in PCB fabrication and assembly. With deep technical know-how and a commitment to quality, they provide the ideal solution for companies seeking high-performance Industrial automation PCB assembly.

Whether you’re developing smart sensors, robotic platforms, or advanced communication modules, Global Well PCBA has the tools, technology, and expertise to bring your vision to life.